|

| April 14, 2015 | Volume 11 Issue 14 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Totally new 3D-printing technology is sci-fi tech right out of the movies

By Designfax

Sometimes you just have to see it to believe it.

Inspired in part by a scene in Terminator 2, the new Continuous Liquid Interface Production (CLIP) 3D-printing technology from a company called Carbon3D harnesses light and oxygen to grow objects from a pool of resin instead of printing them layer by layer.

The tech's creators say that its main advantage (besides being incredibly cool) is that it can create single-material parts 25 to 100 times faster than conventional 3D printing.

"We believe that CLIP technology is a step function advance over the current state-of-the-art for polymer-based 3D printing," Rob Schoeben, chief marketing and strategy officer of Carbon3D, told Designfax. "With that said, by transforming 3D printing from a mechanical process to one governed by software and chemistry, there is significant opportunity for ongoing technical advancement in speed, part quality, and materials. Right now, we are very much focused on delivering our first product within the next 12 months and getting it into the hands of designers and engineers to see what they can do with it."

CLIP "grows" parts from a pool of resin using a photopolymer process.

Carbon3D is a Silicon Valley-based company that was founded in 2013 in Chapel Hill, NC. The CLIP technology was originally developed by Professor Joseph DeSimone, Professor Edward Samulski, and Dr. Alex Ermoshkin and introduced simultaneously at TED 2015 and to the scientific community as the cover story in the March 20, 2015, issue of Science magazine.

"We were definitely inspired by the Terminator 2 clip," said Schoeben. "The co-founders thought, 'Why couldn't a 3D printer work like what we saw with T-1000 in Terminator 2, where you have a 3D object rise from a puddle in essentially real time with essentially no waste to make a real object?'

"We wanted to come up with a way to actually get this to work. That was our challenge. To make Hollywood's fiction a reality, we brought a new perspective to traditional 3D printing. Specifically, we brought our expertise in chemistry and physics to an industry that relied on mechanical processes."

"From a photopolymer chemistry perspective, it is well understood that oxygen inhibits polymerization," said Schoeben. "Where Joe [DeSimone] and the founding team thought differently than everyone else was to explore whether this oxygen inhibition could be used for good. It turned out that by harnessing light and oxygen, together, they could grow a part continuously without it ever getting stuck to the window. It was fast, and the part had no layers. They knew they were on to something big."

Through a sponsored research agreement between UNC-Chapel Hill and Carbon 3D, the team is currently pursuing advances to the technology, as well as new materials that are compatible with it. CLIP enables a very wide range of materials to be used to make 3D parts with novel properties, including elastomers, silicones, nylon-like materials, ceramics, and biodegradable materials. The technique itself provides a blueprint for synthesizing novel materials that can further research in materials science.

The process uses a standard .stl file to continuously grow commercial quality parts.

DeSimone said in a recent American Association for the Advancement of Science article that the technology "can also make materials with high elasticity for athletic shoes or high dampening for applications like engine motor mounts for vibrational control. ... The process lends itself to the entire range of properties that people want in their parts."

More about how CLIP works

As the CLIP tech developers put it, "Existing 3D printing, or additive manufacturing technology, is really just 2D printing, over and over again." As a result, 3D-printed parts take many hours, even days, to produce and can sometimes be mechanically weak due to their shale-like layers.

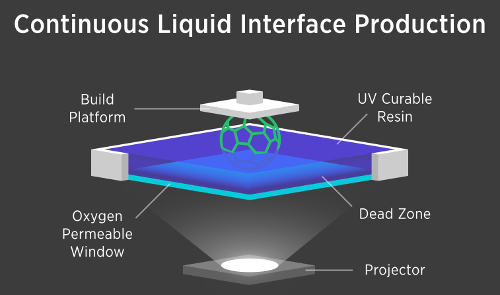

Using a tunable photochemical process instead of the traditional mechanical approach, Carbon3D's CLIP technology eliminates these shortcomings to rapidly transform 3D models into physical objects. By carefully balancing the interaction of UV light, which triggers photo polymerization, and oxygen, which inhibits the reaction, CLIP continuously grows objects from a pool of resin faster than traditional 3D printing.

At the heart of the CLIP process is a special window that is transparent to light and permeable to oxygen, much like a contact lens. By controlling the oxygen flux through the window, CLIP creates a "dead zone" in the resin pool just tens of microns thick (about 2 to 3 diameters of a red blood cell) where photopolymerization cannot occur. As a series of cross-sectional images of a 3D model is played like a movie into the resin pool from underneath, the physical object emerges continuously from just above the dead zone.

Conventionally made 3D-printed parts can have mechanical properties that vary depending on the direction the parts were printed because of the layer-by-layer approach. Much more like injection-molded parts, CLIP produces consistent and predictable mechanical properties, smooth on the outside and solid on the inside.

For the time being, the technology seems ripe to fill varied small-part niche needs. The developers did not comment on how physically large the technology could scale.

"In addition to using new materials, CLIP can allow us to make stronger objects with unique geometries that other techniques cannot achieve, such as cardiac stents personally tailored to meet the needs of a specific patient," said DeSimone. Custom coronary stents, dental implants, or prosthetics could also be 3D printed on-demand in a medical setting.

Sources: Carbon3D, UNC-Chapel Hill

Published April 2015

Rate this article

View our terms of use and privacy policy